Vinews

No. 4 — April 15, 2019

Contents:

- Cross-resistance of Fruit Flies Drosophila spp. in New York

- How Much to Apply?

- Bud Break — Looking Back

- Potential for Frost Damage in April — Unlikely

- Phomopsis Cane and Leaf Spot

Cross-resistance of Fruit Flies Drosophila spp. in New York

Last week in Fredricksburg, Texas, at the National Viticulture and Enology Leadership Conference, it was reported that fruit flies have evolved resistance to Mustang Max, Assail and malathion. The fruit flies were collected from a New York state vineyard in which Mustang Max had failed to control the fruit flies. This vineyard had been treated for three years with Mustang Max to control fruit flies. Hans Walter Peterson from Cornell said this particular population of fruit flies has developed cross-resistance to three different chemical classes (Table 1). This particular fruit fly population is susceptible to Delegate (spinetoram).

What does this mean for managing fruit flies in grape cultivars susceptible to sour rot? I strongly recommend that Delegate be used in rotation with other insecticides. If you have been using Mustang Max to control fruit flies for the past two years, then you should monitor these vineyards very closely after an application. If fruit flies are abundant after an insecticide application, this would provide some indication that fruit flies have developed insecticide resistance. Do not repeatedly apply Mustang Max to control fruit flies this season. Be sure to rotate insecticides from different chemical classes. See page 93 of the 2019-2020 Midwest Fruit Pest Management Guide for chemical classes of insecticides. For more information on chemical classification of insecticides.

Table 1. Insecticides in which fruit flies Drosophila spp. have developed crossresistance to in a vineyard in New York state.

| Trade name | Common Name | IRAC | Sub-group or active ingredient |

|---|---|---|---|

| Assail | acetamiprid | 4A | Neonicotinoids |

| Malathion | malathion | 1B | Organophosphates |

| Mustang Max | zeta-cypermethrin | 3A | Pyrethroids/Pyrethrins |

The cost of managing fruit flies will increase as less Mustang Max is used in your fruit fly management program. Costs per acre per application will increase between 4 to 13 times more than an application of Mustang Max (Table 2).

Table 2. Cost per acre per application for selected insecticides that provide control of fruit flies Drosophila spp.

| Product | Unit cost1 | Use rate | Cost of product per application |

|---|---|---|---|

| $ | acre | $ | |

| Assail 30 SG | 69.95 lb | 2.5-5.3 oz | 23.17 |

| Delegate WG | 9.55 oz | 3-5 oz | 47.75 |

| Malathion2 | 42.95 gal | 1.88 lbs ai | 16.11 |

| Mustang Max | 115.95 gal | 4 oz | 3.62 |

1 Prices may very based on your chemical supplier.

2 Malathion is available from a number of chemical suppliers and formulations (Amount of active ingredient per gallon) varies by supplier. Often fruit flies or Drosophila may not be listed on the label within the label section for grapes. Typical formulations are 5 or 8 lbs active ingredient per gallon.

The fact that fruit flies have developed resistance to Mustang Max and other insecticides should not be all that surprising, especially to those in the entomology world. Early work by the renowned geneticists James Crow from the University of Wisconsin-Madison was instrumental in establishing Drosophila as the genetic model for resistance studies. At that time (1957) the interest was in understanding adult Drosophila resistance to DDT. It was a short time later (1962) that Rachel Carson published the book Silent Spring. The book Silent Spring and Rachel Carson are credited with the eventual ban of DDT. Interestingly, the Drosophila population James Crow had been evaluating had been exposed to DDT over a period of 25 years in the laboratory. At that time, it was shown that DDT resistance in adult Drosophila was the result of polygenic resistance. In field collected populations of Drosophila resistance is often the result of overtranscription of P450 genes. Briefly, cytochrome P450 monooxygenases are important in regulating the metabolism of pesticides as well as play an important role in other metabolic regulation. Cytochrome P450 monooxegenase mediated resistance is a very common type of metabolism based insecticide resistance. Since the fruit flies from New York have evolved cross-resistance to three different chemical classes of insecticides this would suggest that Cytochrome P450 monooxygenases are likely involved since Cytochrome P450 monooxegenases can confer crossresistance independent of the insecticides target site. On the other hand, if the New York fruit fly population was resistant only to a single insecticide such as Mustang Max this would provide strong evidence that resistance is the result of a target site modification.

Factors leading to insecticide resistance

A number of factors play a role in the selection of insecticide resistant fruit flies. The goal of applying an insecticide is to control the fruit flies. Within the population of fruit flies there are rare variant individual fruit flies that have the ability to detoxify the applied insecticide. These rare variants survive the insecticide application whereas the majority of the population is susceptible to the insecticide and die. Applying an insecticide to a crop is in effect applying selection pressure to the fruit fly population.

This selection pressure is impacted by the dose or rate of the insecticide applied as well as the number or times the insecticide is applied. Applying the recommended full label rate at three different application timings is greater selection pressure than applying the full recommended label rate one time. In addition to the rate and the number of times the insecticide is applied, the persistence or the insecticide or residual also results in selection pressure. The longer the insecticide persists and remains active the greater the selection pressure of the insecticide. Additionally, the rate of reproduction of the fruit fly plays a role in the development of resistance to insecticides. Fruit flies have tremendous reproductive potential. A single female can live for several weeks and lay 400 to 500 eggs. A new generation emerges approximately every 10 days at 77 degrees F. The population will increase from one female to 16 million females in approximately a month given the environmental conditions are right and all individual females survive. Therefore when a single fruit fly is resistant to an insecticide, the observation that a particular insecticide is no longer efficacious will be very pronounced. How? Fruit flies will still be swarming about the vineyard after an application of an insecticide.

The reproduction rate plays a very important role in insecticide resistance development. In contrast to the fruit fly, the Japanese beetle female lays approximately 50 eggs and there is a single generation per year. Additionally, unlike fruit flies, Japanese beetles are strong flyers and can travel several miles. This results in genetic heterogeneity or mating between the Japanese beetles that are naturalized within your vineyard and beetles flying into your vineyard from outside areas. This in effect may reduce the potential for selection of resistant Japanese beetles. Since a rare variant beetle that is insecticide resistant may mate with an insecticide susceptible beetle that has flown into the vineyard.

In conclusion, fruit flies in a New York vineyard have evolved resistance to insecticides from three different chemical classes. This population of fruit flies developed resistance in a vineyard that had been sprayed for 3-years with Mustang Max. At this time, the fruit fly population remains susceptible to Delegate. In Missouri vineyards in which Mustang Max has been applied for two years or more for the control of fruit flies in an effort to manage sour rot, a resistance management plan should be implemented. The plan should include a spray schedule that limits Mustang Max applications and rotates to insecticides from other chemical classes. Additionally, in vineyards in which Mustang Max has been applied for control of fruit flies for sour rot management, these vineyards should be monitored for efficacy after an insecticide application.

How Much to Apply?

Often I receive emails asking me how much of a product should be applied. Seems like a very straight-forward question, but it is not. Many of the pesticides used in agricultural production, which includes grape growing, come in various formulations. As an example, Rely herbicide initially was introduced formulated at 1.00 pound of glufosinate-ammonium per gallon. The application rate was 3 to 5 quarts per acre. Next, Rely was introduced as Rely 200 and formulated at 1.67 lbs of glufosinate-ammonum per gallon. The use rate for Rely 200 was 57.5 to 115 fluid ounces per acre. Finally, Rely was introduced as Rely 280 and formulated at 2.34 lbs of glufosinate-ammonium per gallon. The use rate for Rely 280 is 48-82 fluid ounces per acre. In addition there are the generic glufosinate-ammonium herbicides. Interline would be an example of generic and is formulated at 2.34 lbs of glufosinate-ammonium per gallon. The use rate for Interline is 48-82 fluid ounces per acre.

Asking the question of how much of a product should be applied per acre is dependent on the formulation. How many pounds of active ingredient per gallon or the percent active ingredient. It does make a difference.

An example of how formulations make a difference. When Rely 280 was introduced a grape grower applied the product at the Rely 200 use rate of 115 ounces per acre. This amounted to applying 0.6 more pounds of the active ingredient per acre. What happened next? The vineyard received over 8 inches of rain since the Rely application, which suggests that there was the potential for leaching. The vineyard is planted on course soil (sandy soil) which likely resulted in Rely infiltrating deep into the soil profile. Most all grape plants were showing visual injury symptoms of chlorotic shoots, and upward cupped leaves (Figure 1). The injury symptoms were not apparent on the older leaves, suggesting the material was translocated to the growing regions (meristematic tissues). There was no symptomology on the grapes leaves that would have suggested overspray or spray drift.

Glufosinate ammonium is very mobile in the soil and may travel though the soil unretarded. The half-life of glufosinate varies based on a number of factors, soil type, temperature, and soil moisture, with half lifes reported ranging from 3 to 70 days. Soils with higher organic matter content will degrade glufosinate ammonium at a faster rate compared to soils (sandy soils) with lower organic matter content. Glufosinate ammonium can potentially be leached into the growing root zone of grapes, but is there evidence that glufosinate can cause damage to plants by root uptake?

The herbicidal effects of glufosinate ammonium have been demonstrated after uptake in hydroponics (You and Barker 2002) and also uptake from the soil in potted plants (You and Barker, 2004). In these studies, besides noting visual herbicide injury symptoms, ammonium ion NH4 + accumulation was quantified in shoots. Glufosinate ammonium works by mimicking glutamate which results in the inhibiting Glutamine synthetase with the end result being an increase of ammonium ion in the plants. As ammonium ion increases in the plant, photosynthesis stops. Visual symptoms of glufosinate ammonium in plants are upward cupping of leaves, and leaf and shoot yellowing (chlorosis).

The take home message here is, read the label that came with the product!

References cited

You, W. and A. V. Barker. 2002. Herbicidal actions of root-applied glufosinate ammonium on tomato plants. Hort. Sci. 127:200-2004.

You, W. and A. V. Barker. 2004. Effects of soil-applied glufosinate-ammonium on tomato plant growth and ammonium accumulation. Commun. Soil Sci. Plan. 35:1945-1955.

For grape growers needing conversion for small amounts of pesticides, see the link below:

Mixing small spray quantities of pesticides

Bud Break — Looking Back

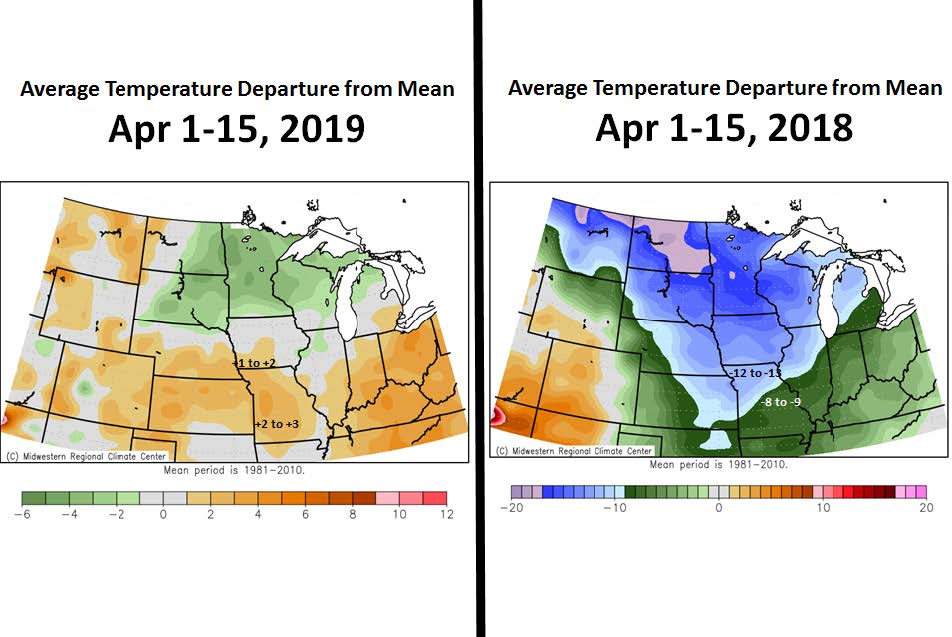

A year ago, average temperatures were trending 8 to 13 degrees F below the mean for the period of April 1–15, 2018 (Figure 2). What a difference a year makes. In comparison, average temperatures for the period of April 1–15 are departing 2 to 3 degrees F above the mean. In 2018, bud break was occurring at the very end of April into the first couple of days of May. This seasons above normal average temperatures will likely result in bud break being completed within the next five days.

Potential for Frost Damage in April — Unlikely

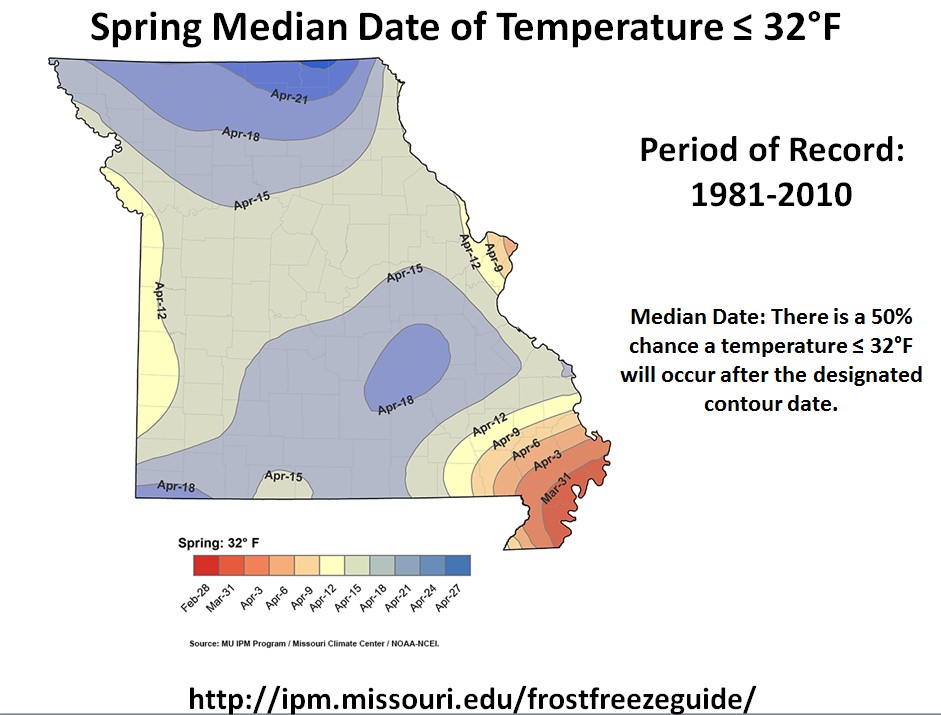

The long-range low temperature forecast through April has no temperatures predicted below 32 degrees F. The frost freeze guide predicts that most Missouri counties have less than a 50 percent chance of temperatures below 32 degrees after April 15 (Figure 3). At this point in the season below 32 degree temperatures are unlikely through the end of April.

Phomopsis Cane and Leaf Spot

With bud break taking place over the next week depending on the cultivar and location, your concern should turn to protecting young tissue after bud break from Phomopsis (Phomopsis viticola) infections. Phomopsis infections occur during cool wet weather. The cool wet weather is when spores release for infection. The optimum temperature for shoot and leaf infections is between 60 to 68 degrees F with at least 6 hours of tissue wetness for infection. Average April high temperatures are near 60 degrees F and this year temperatures are trending 2 to 3 degrees above the average normal high temperature. These temperatures are ideal for Phomopsis infections, especially when tissues remain wet. Next week there is a lot of wet cloudy weather forecast. Remember cloudy weather often extends the wetting period of grape tissue, thereby extending the infection period.

To protect grape leaves and shoots from Phomopsis infections a protective fungicide should be applied at ½- to 1-inch shoots. Fungicide products that provide good protection contain the active ingredient mancozeb. Mancozeb also provides excellent protection to black rot and downy mildew. Some common trade names of mancozeb fungicides are, Dithane M45, Manzate Pro-Stick, and Penncozeb 75DF.